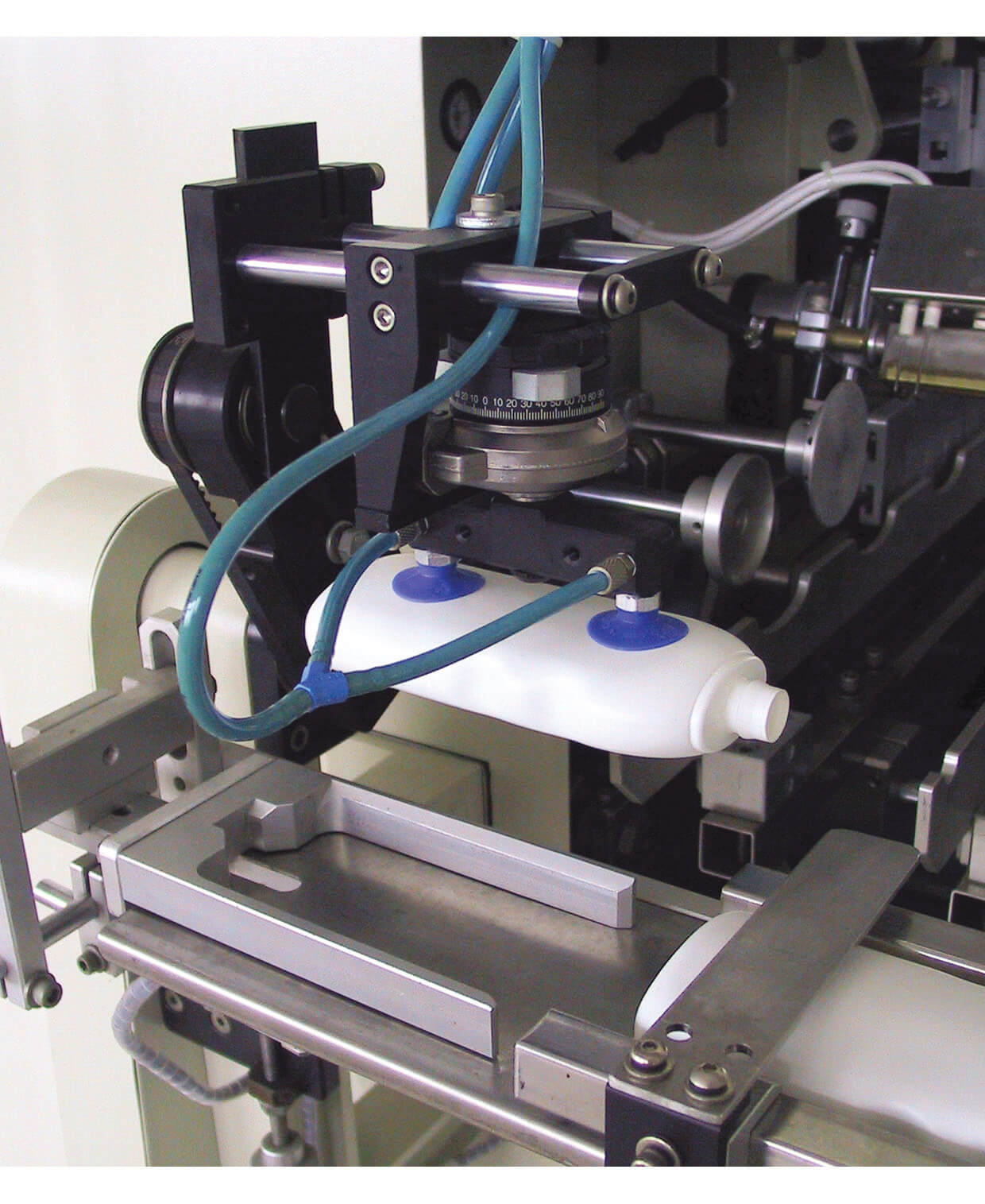

Designed for high volume single to multicolor screen printing, it can print round, oval and rectangle container or other special products.

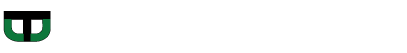

Screen Train equipped with semi-auto loading system, tailor made automatic feeding system can also be customized.

Screen train provides 'One-stop'solution from one to six colors screen printing. Its synchronized mechanical design provides stable transmissions, PLC control system for simple operation, makes its registration more accurate and production more efficiency.

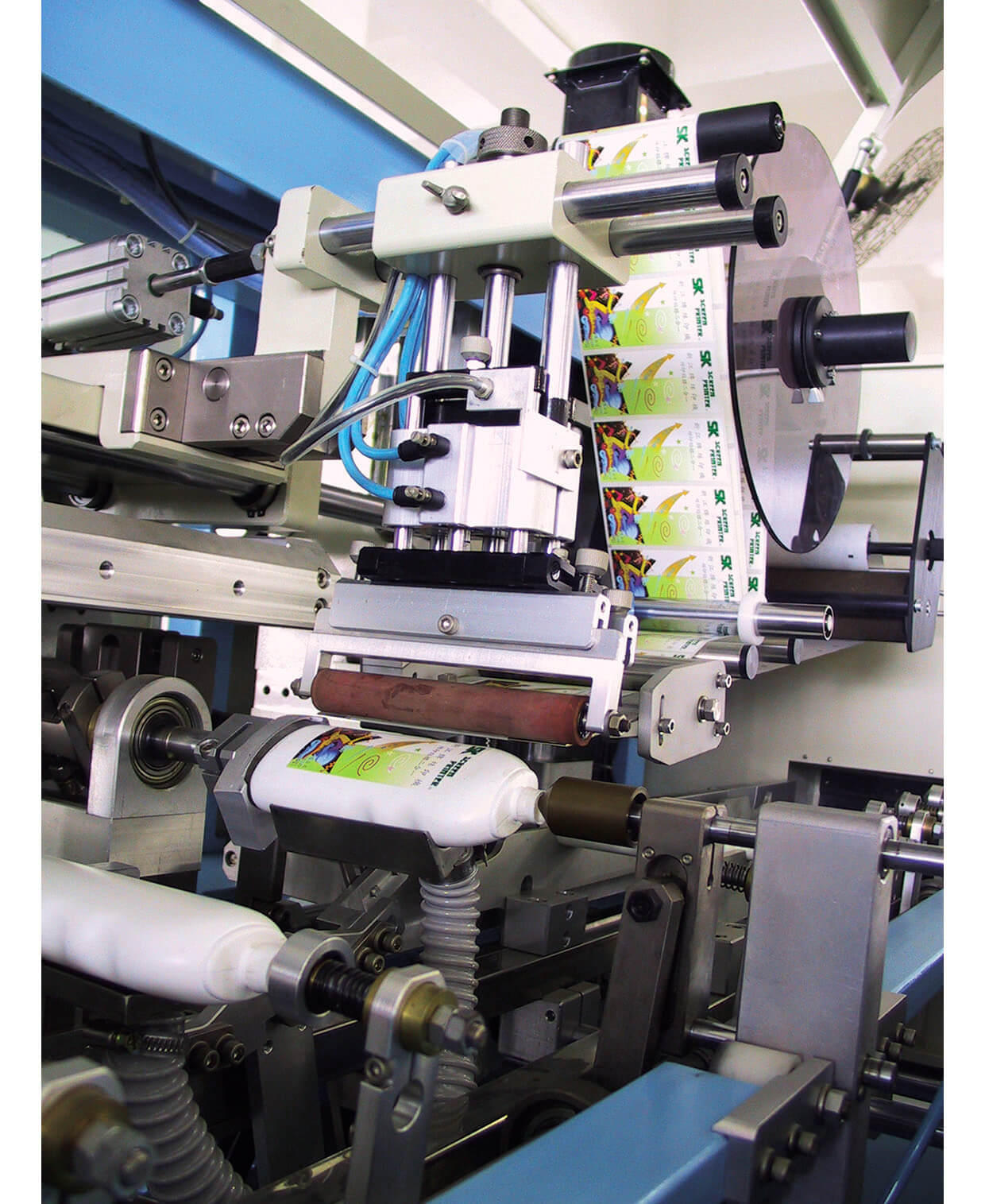

According to different requirement, automatic label printing system can be installed.

Features

Loading

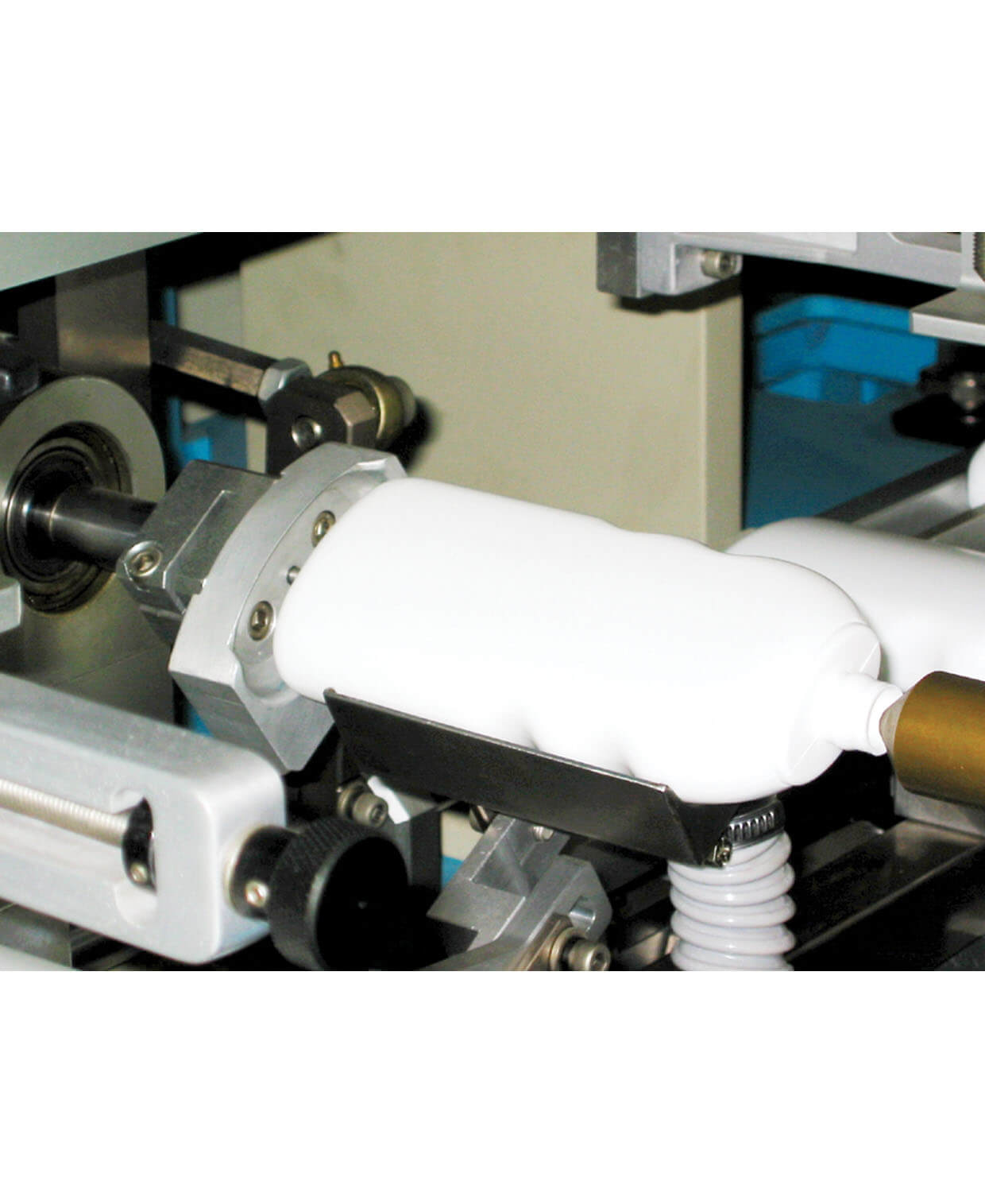

- Semi-auto loading system

- Customized automatic loading and feeding system is available upon request

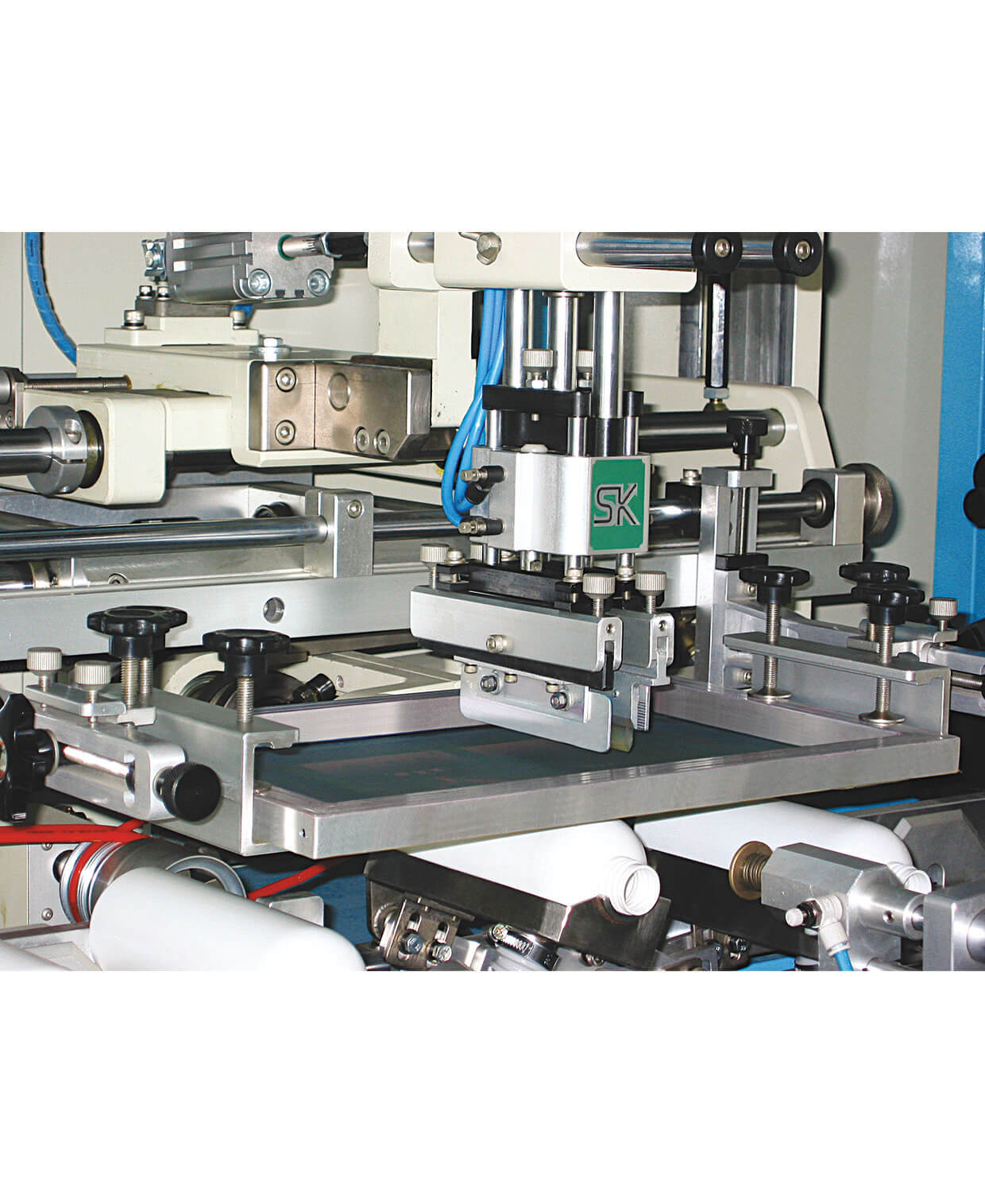

Operation system

PLC system

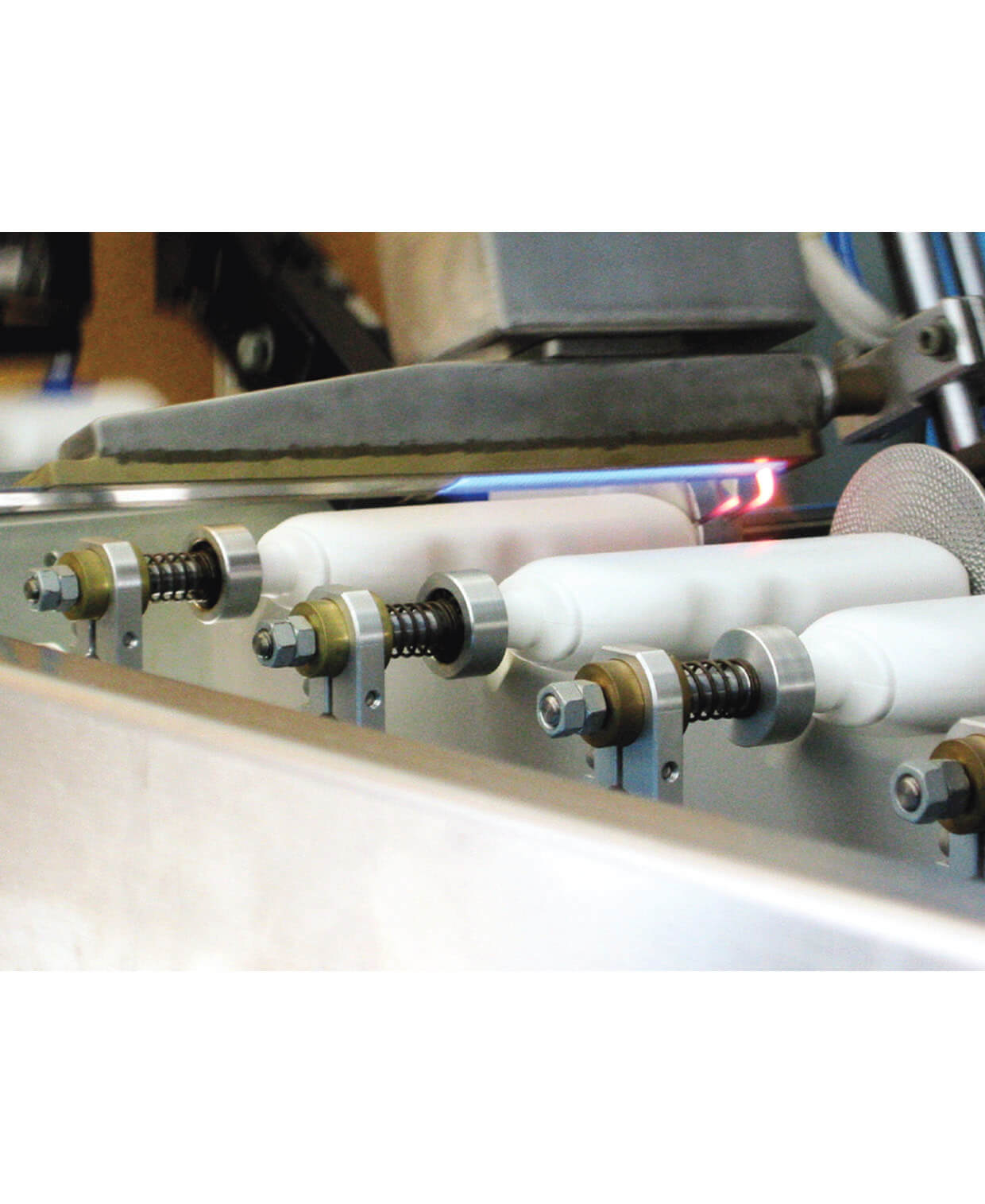

UV curing

Automatic

Optional

- Double-side printing for flat bottles

- Automatic label printing system

Specifications

Printing product size (dia. × length)

- Round items: ⌀ 130mm × 280mm

- Oval items: ⌀ 130mm × 280mm

Maximum printing area

- Round items: 240mm × 177mm

- Oval items: 120mm × 200mm

Maximum running speed

- Round items: 66 pcs/min

- Oval items: 75 pcs/min

UV lamp power

- 2.4kw/6"

- 3.2kw/8"

- 4kw/10"

Power requirement

380V 3phase 50Hz

Compressed air pressure

5–7bar

Power consumption

5.4kw/6.2kw/7kw each unit

Main machine dimension (L × W × H)

3650mm × 2700mm × 1865mm

Extended machine dimension (L × W × H)

1900mm × 1200mm × 1865mm

Weight

3265kg

Number of colors

1–6 colors